Industrial-grade electric screw driver mainly appears in production lines. Therefore they are a good helper for the factory to improve work efficiency. The quality of the tools will have a certain impact on the production of the factory. Therefore, it is necessary to inspect and purchase high-quality electric screwdrivers.

#1. Main factors affecting the performance of electric screw drivers

- Torque accuracy

- Noise

- Degree of heat

- Bit stability

- Brake function

Torque accuracy is an important indicator to ensure the degree of screw fastening. A good electric screwdriver can automatically brake after tightening the correct number of turns, without multiple brakes.

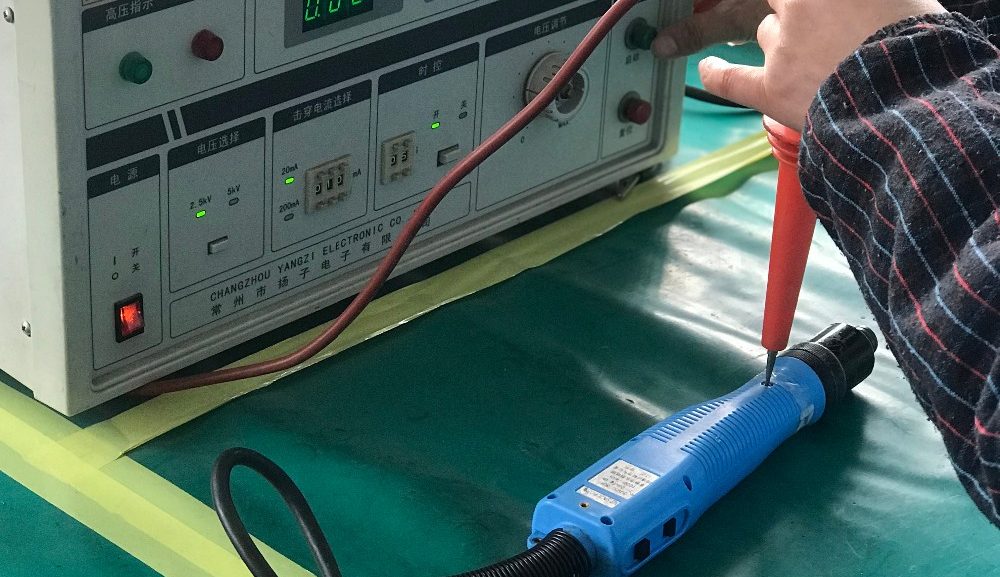

#2. Method of detecting an electric screwdriver

Step 1 Check the hardware section

1. The outer packaging of the electric screw driver should be clear in the pattern, not damaged. The plastic box is strong, and the buckle of the opening plastic box should be firm and durable.

2. The appearance of the electric screwdriver should be uniform in color, the surface of the plastic part has no obvious shadow and dent, there should be no scratches or bump marks. The assembly misalignment between the outer parts is ≤0.5mm, the aluminum casting paint is smooth and beautiful without defects, the whole machine surface It should be free of oil and stains. When holding with your hand, the handle of the switch should be flat. The length of the cable should generally be no less than 2 meters.

3. The nameplate parameters of the electric batch shall be the same as those on the CCC certificate. On the one hand, the manufacturer’s and manufacturer’s detailed address and contact details should be available on the instruction manual. On the other hand, the serial number of the product traceable should be on the nameplate or certificate.

Step 2 Check product performance

1. Hold the electric screwdriver with your hand, turn on the power, and frequently operate the switch to make the tool start frequently. Observe whether the on/off function of the electric screwdriver switch is reliable. At the same time, observe whether there are any abnormalities in the TV sets and fluorescent lamps on the spot. In order to confirm whether there is a valid radio interference suppressor inside the electric screwdriver.

2. Start the power and handle the electric screwdriver for one minute. In principle, the hand should not feel any abnormal vibration. Observe the reversing spark. The reversing spark should not exceed 3/2, generally from the electric screwdriver. Look inside the air inlet, there should be no obvious arc on the surface of the commutator. There should be no abnormal noise during operation.

2. Start the power and handle the electric screwdriver for one minute. In principle, the hand should not feel any abnormal vibration. Observe the reversing spark. The reversing spark should not exceed 3/2, generally from the electric screwdriver. Look inside the air inlet, there should be no obvious arc on the surface of the commutator. There should be no abnormal noise during operation.

3. Repeated torque accuracy or error within 0.3%.

4. If you are tightening the small screws, you need to consider whether the swing range of the bit is too large. After installing the electric bit, start the power and see if the bit is working in a circular motion. It is best not doing the circular motion. The smaller the circle, the better.

5. The size of the fuselage is reasonable, and the heat is not serious or the heat is small for a long time.

6. long service life

7. Low noise during working

#3. Conclusion

Industrial production not only needs to test the performance and quality of electric screwdrivers but also needs to be regularly maintained. The technique of maintaining electric screwdrivers can refer to another article: 5 Tips on How to Use and Maintain Electric Screwdriver

中文

中文

EN

EN