Introduction of electric screwdriver parts

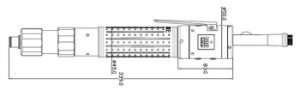

Generally speaking, the structure of the electric screwdriver offen composition with an electric motor, a gear reduction box, a clutch device, a screwdriver head and a protective sleeve, a positive and negative power switch, and a power connection device.

The electric screwdriver has a brushless motor in its plastic case. The plastic housing is both a structural component that supports the motor and additional insulation for the stator core. And the additional insulation of the rotor insulates by a rotating shaft to electrically isolate. The rotor core from the exposed metal parts.

The gearbox is die-cast from aluminum alloy, one end screw to the plastic housing through the intermediate cover. And the other end is threadedly coupled to the outer sleeve of the built-in clutch device. But Two pairs of cylindrical helical gears are arranged in the gearbox.

The clutch device composition with a jaw clutch, a pressure spring, an adjusting nut. And a spindle of a chucking screwdriver head.

How electric screwdriver works

The rotary motion of the driver’s head driven by the motor through the second gear to drive the hollow shaft 4 to rotate. The front end of the hollow shaft is the active part of the jaw clutch. After the motor start, the hollow shaft rotates without load and the screwdriver head is stationary. When the driver bit subject to axial pressure. The hollow shaft spring 1 compress so that the teeth of the end face of the clutch follower 5 mesh with the teeth of the front end clutch active member of the hollow shaft. So that the spindle 13 unidirectionally rotated by the steel ball of the jaw clutch. The spindle pin integrates with the screwdriver head. And the screwdriver head also rotated together to tighten or remove the screw.

After the jaw clutch engaged, the torque can transmittable the three middle steel balls. But in operation, if the required torque or torque is too large. The jaw clutch follower compresses the spring 8 and disengages from the active and the driven members of the jaw clutch to prevent damage to the thread and the motor.

Adjust the torque

The adjusting nut 12 used to adjust the output torque of the driver’s head. Through the working spring 7, the pressing force of the claw clutch follower adjusted to ensure that the jaw clutch can smoothly separate under a certain torque. The amount of torque can achieve by turning the adjusting nut. If the adjusting nut rotates in the direction of the jaw clutch. The spring compress and the transmission torque is large. If the adjusting nut rotated in the opposite direction to the jaw clutch, the spring weak in force and the transmission torque is small. The screw tightening torque can adjust according to the above method to ensure a stable clamping force between the screw and the workpiece. Thus ensuring the assembly quality of the screw and the workpiece.

Now you will know how electric screwdriver work. If any other questions about the electric screwdriver industrial, please write a comment to us or send us an email. Your feedback will be very important to us.

中文

中文

EN

EN